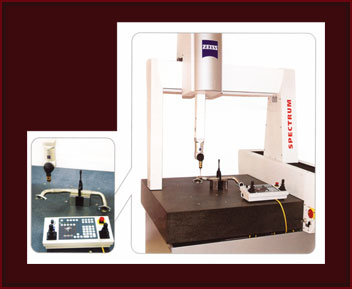

The 3 Axis co-ordinates of EGR Tubes, Turbo Drain Pipes

and Exhaust Bellows are measured on a Carl Zeiss

Co-ordinates Measuring Machine (CMM) having a bed

size of 700 x 500 mm.

This equipment is suitable for measurement of imaginary

co-ordinates over all three axis including parameters,

such as, flatness, con-centricity, co-axiality, parallelism,

waviness etc.

It is also extremely helpful in the measurement of

precision toolings and fixtures developed for manufacturing

and inspection purposes.